https://www.zoro.com/resourcehub/how-to-measure-pipe-and-fitting-sizes/

How to Measure Pipe and Fitting Sizes

Concise guide that covers the key aspects of pipe and fitting measurements. It is an essential tool for anyone working with pipes and fittings.

Determining what size pipes you need for your project can be confusing. Many people assume pipe size is the outer diameter of the pipe—but “pipe size” actually refers to what is called “nominal diameter.”

Fittings can be just as confusing. Their inside diameters must be large enough to fit over the pipe's outside diameter. A half-inch plastic elbow, for example, has an outside diameter of about 1-1/4 inches.

Use this guide to help you find the pipe and fitting sizes you need for your next project.

How To Measure Pipes and Tubes

Convert Actual Diameter to Nominal Diameter

The easiest way to find what nominal pipe size you need is to use follow these steps and use the conversion chart below.

| For Female Threads1. Measure the Inside Diameter (ID) of your pipe or pipe fitting (use a ruler or tape measure).2. Use the chart on this page to find the nominal diameter (pipe size). |  |

|---|---|

Nominal Diameter Conversion Chart

(All Measurements in Inches)

| Outside or Inside Diameter | Decimal Equivalent | Nominal Diameter | Typical Threads Per Inch |

|---|---|---|---|

| 5/16 | 0.313 | 1/16 | 27 |

| 13/32 | 0.405 | 1/8 | 27 |

| 35/64 | 0.540 | 1/4 | 18 |

| 43/64 | 0.675 | 3/8 | 18 |

| 27/32 | 0.840 | 1/2 | 14 |

| 1-3/64 | 1.050 | 3/4 | 14 |

| 1-5/16 | 1.315 | 1 | 11-1/2 |

| 1-21/32 | 1.660 | 1-1/4 | 11-1/2 |

| 1-29/32 | 1.900 | 1-1/2 | 11-1/2 |

| 2-3/8 | 2.375 | 2 | 11-1/2 |

| 2-7/8 | 2.875 | 2-1/2 | 8 |

| 3-1/2 | 3.500 | 3 | 8 |

| 4 | 4.000 | 3-1/2 | 8 |

| 4-1/2 | 4.500 | 4 | 8 |

Pipes vs. Tubing

Pipes vs. Tubing

Pipe and tubing are not measured the same way. Tubing is measured and named based on the actual outside diameter of the tube.

PEX, or Cross-Linked Polyethylene Tubing, is another technology fast becoming popular, and it is measured and named by inside diameter.

Example:

| Pipe vs. Tubing | Outside Diameter |

|---|---|

| 1/2” size pipe | 27/32” |

| 1/2” size tubing | 1/2” |

Select Thread Type

One of the most common thread types is National Pipe Thread (NPT). These come in male (NPT, MPT, or MNPT) and female (FPT or FNPT). These are usually tapered threads used in joining and sealing pipes.

Another common thread is National Standard Free-Fitting Straight Mechanical Pipe Thread (NPSM). These straight thread pipes are typically used for mechanical joints.

BSP thread form stands for British Standard Pipe. It is based on trade size rather than actual diameter.

Shop Pipes and Fittings

Select the plumbing application you need for your next project.

| Pipes & Pipe NipplesShop All Pipes | Black PipesStainless Steel PipesGalvanized PipesBrass PipesPVC & CPVC Pipes |

|---|---|

FittingsShop All Fittings

Product Compliance and Suitability

The product statements contained in this guide are intended for general informational purposes only. Such product statements do not constitute a product recommendation or representation as to the appropriateness, accuracy, completeness, correctness or currentness of the information provided. Information provided in this guide does not replace the use by you of any manufacturer instructions, technical product manual, or other professional resource or adviser available to you. Always read, understand and follow all manufacturer instructions.

PVC Pipe Sizes: A Guide To Sizes and Dimensions

Discover the essential information about PVC pipe sizes and dimensions in this guide. Learn more about pipes and find the right fit for your project.

3/19/2021 – Zoro Staff

Depending on the project at hand, you may need to buy new PVC pipes. PVC pipes vary in size and are broken down into three main categories: schedule 40, schedule 80, and schedule 120. To avoid misuse, plumbing malfunctions, or pushing back a piping project, it’s helpful to do your research and find the right product fit. It could save you and your team time and money from reordering materials or fixing future pipe issues.

PVC pipes are measured on a nominal system. This means all measurements are based on the types of structures versus specific measurements. For instance, 0.84 inches measured from one pipe's end to another is classified as a one-inch pipe. There are also different uses for each type of pipe schedule. Keep reading to understand each PVC pipe's size and uses for your next job.

How to Measure Your Current PVC Pipe Size

| Your Measurement | Average Outer Diameter (OD) |

|---|---|

| Diameter | PVC Pipe Size Translation |

| 0.84” | ½” |

| 1.05” | ¾” |

| 1.315” | 1” |

| 1.66” | 1 ¼” |

| 1.9” | 1 ½” |

| 2.375” | 2” |

| 3.5” | 3” |

| 4” | 3 ½” |

| 4.5” | 4” |

| 5.563” | 5” |

| 6.625” | 6” |

| 8.625” | 8” |

| 10.75” | 10” |

| *Works for Schedule 40 and Schedule 80 PVC pipes. |

Pipe measurements are calculated on a nominal scale. This means their measurements reference structures at hand over true scale measurements. To help translate the correct size of pipes you need, we included a helpful guide above.

Here’s a step-by-step guide to using the chart:

- Place your pipe on a hard surface and face one end towards you.

- Grab a tape measure or ruler to measure your pipe’s right outer edge to its left outer edge. Keep your ruler as level as possible while measuring.

- Now, pair “Your Measurement” with the “Average OD” referencing the chart above.

- Pick out your pipes based on the Average OD your measurement paired with.

Keep in mind, these measurements refer to the outer edge of the pipe, not the inner. Depending on the schedule of pipe you need, your inner measurements may fluctuate.

Schedule 40 PVC Pipe Dimensions

| Nominal Pipe Size (Inches) | Outside Diameter (OD) | Min. Wall Thickness | Inside Diameter (ID) | Linear Weight Density (Wt. / Ft.) |

|---|---|---|---|---|

| 1/8 | 0.405 | 0.068 | 0.249 | 0.051 |

| 1/4 | 0.540 | 0.086 | 0.344 | 0.086 |

| 3/8 | 0.675 | 0.091 | 0.473 | 0.115 |

| 1/2 | 0.840 | 0.109 | 0.602 | 0.170 |

| 3/4 | 1.050 | 0.113 | 0.804 | 0.226 |

| 1 | 1.315 | 0.133 | 1.029 | 0.333 |

| 1 1/4 | 1.660 | 0.140 | 1.360 | 0.450 |

| 1 1/2 | 1.900 | 0.145 | 1.590 | 0.537 |

| 2 | 2.375 | 0.154 | 2.047 | 0.720 |

| 2 1/2 | 2.875 | 0.203 | 2.445 | 1.136 |

| 3 | 3.500 | 0.216 | 3.042 | 1.488 |

| 3 1/2 | 4.000 | 0.226 | 3.521 | 1.789 |

| 4 | 4.500 | 0.237 | 3.998 | 2.118 |

| 5 | 5.563 | 0.258 | 5.016 | 2.874 |

| 6 | 6.625 | 0.280 | 6.031 | 3.733 |

| 8 | 8.625 | 0.322 | 7.942 | 5.619 |

| 10 | 10.750 | 0.365 | 9.976 | 7.966 |

| 12 | 12.750 | 0.406 | 11.889 | 10.534 |

| 14 | 14.000 | 0.437 | 13.073 | 12.462 |

| 16 | 16.000 | 0.500 | 14.940 | 16.286 |

| 18 | 18.000 | 0.562 | 16.809 | 20.587 |

| 20 | 20.000 | 0.593 | 18.743 | 24.183 |

| 24 | 24.000 | 0.687 | 22.544 | 33.652 |

Schedule 40 pipes are typically white or silver but can be found in other colors. These pipes are thinner than schedule 80s and 120s. This allows fluids to pass through faster than other pipe schedules. This style upholds great pressure, even for cold water systems. In hot temperatures, all three schedules are able to withstand up to 140 degrees.

Schedule 40 pipes are commonly used for drainage around buildings and for gas and water lines. The pressure rating for this pipe schedule is 120 to 810 pounds per second inch (PSI). As a result, schedule 40 pipes are commonly used for potable water systems, golf course construction, or pools and spas.

Schedule 80 PVC Pipe Dimensions

| Nominal Pipe Size (Inches) | Outside Diameter (OD) | Min. Wall Thickness | Inside Diameter (ID) | Linear Weight Density (Wt. / Ft.) |

|---|---|---|---|---|

| 1/8 | 0.405 | 0.095 | 0.195 | 0.068 |

| 1/4 | 0.540 | 0.119 | 0.288 | 0.110 |

| 3/8 | 0.675 | 0.126 | 0.407 | 0.153 |

| 1/2 | 0.840 | 0.147 | 0.546 | 0.225 |

| 3/4 | 1.050 | 0.154 | 0.742 | 0.305 |

| 1 | 1.315 | 0.179 | 0.957 | 0.450 |

| 1 1/4 | 1.660 | 1.191 | 1.278 | 0.621 |

| 1 1/2 | 1.900 | 0.200 | 1.500 | 0.754 |

| 2 | 2.375 | 0.218 | 1.939 | 1.043 |

| 2 1/2 | 2.875 | 0.276 | 2.290 | 1.594 |

| 3 | 3.500 | 0.300 | 2.864 | 2.132 |

| 4 | 4.500 | 0.337 | 3.786 | 3.116 |

| 6 | 6.625 | 0.432 | 5.709 | 5.951 |

| 8 | 8.625 | 0.500 | 7.565 | 9.040 |

| 10 | 10.750 | 0.593 | 9.493 | 13.413 |

| 12 | 12.750 | 0.687 | 11.294 | 18.440 |

| 14 | 14.000 | 0.750 | 12.410 | 22.119 |

| 16 | 16.000 | 0.843 | 14.213 | 28.424 |

| 18 | 18.000 | 0.937 | 16.014 | 36.487 |

| 20 | 20.000 | 1.031 | 17.814 | 44.648 |

| 24 | 24.000 | 1.218 | 21.418 | 36.341 |

Schedule 80 pipes are thicker than schedule 40 pipes, but still not the thickest. These pipes are usually dark gray in color but may vary. Schedule 80 PVC pipes are built thicker and stronger than schedule 40s, and can handle higher pressures with a rating of 210 to 1230 PSI. They’re often used for chemical processing, industrial plating, deionized water lines, and wastewater treatment management.

Keep in mind, the thicker the pipe does not equal pipe security. Depending on the solutions you’d be transporting and the flow rate you’d like, mishaps can happen if you don’t choose the correct size and fit. For instance, if you use a heavy pipe for general solution purposes, your flow could be slower than needed.

Schedule 120 PVC Pipe Dimensions

| Nominal Pipe Size (Inches) | Outside Diameter (OD) | Min. Wall Thickness | Inside Diameter (ID) | Linear Weight Density (Wt. / Ft.) |

|---|---|---|---|---|

| 1/2 | 0.840 | 0.170 | 0.480 | 0.236 |

| 3/4 | 1.050 | 0.170 | 0.690 | 0.311 |

| 1 | 1.320 | 0.200 | 0.891 | 0.464 |

| 1 1/4 | 1.660 | 0.215 | 1.204 | 0.649 |

| 1 1/2 | 1.900 | 0.225 | 1.423 | 0.787 |

| 2 | 2.380 | 0.250 | 1.84 | 1.111 |

| 2 1/2 | 2.880 | 0.300 | 2.239 | 1.615 |

| 3 | 3.500 | 0.350 | 2.758 | 2.306 |

| 4 | 4.500 | 0.430 | 3.574 | 19.000 |

| 6 | 6.625 | 0.532 | 5.434 | 36.390 |

| 8 | 8.625 | 0.719 | 7.189 | 60.440 |

| 10 | 10.750 | 0.844 | – | 98.290 |

| 12 | 12.750 | 1.000 | – | 125.490 |

| 14 | 14.000 | 1.094 | – | 150.790 |

| 16 | 16.000 | 1.219 | – | 192.430 |

| 18 | 18.000 | 1.375 | – | 244.140 |

| 20 | 20.000 | 1.500 | – | 296.370 |

| 22 | 22.000 | 1.625 | – | 353.610 |

| 24 | 24.000 | 1.812 | – | 429.390 |

Schedule 120 pipes are one of the thickest pipes on the market. With their density, they’re routinely used for non-corrosive or general corrosive projects with less reactive ingredients. Automotive and construction establishments frequently use these materials for maximum durability. Schedule 120’s pipe thickness helps slow down mild to high-pressure systems with a rating of 380 to 1,010 PSI.

Depending on the construction site you’re working on, contact your state for building code regulations. To avoid miscommunication, ensure you find out pipe schedules needed to properly meet local requirements.

Once you have your pipe sizes figured out, you’ll be able to move onto the next step: ordering pipe values. To help control your pipe flow, figure out which size valves you may need. When you’re ready to install your pipes and valves, be sure to reference our guide. As your team needs more materials or installation information, be sure to reference Zoro’s site for expert tips, tricks, and product needs.

Sources: Hunker

< hr>

How to Join and Loosen Galvanized Pipe Fittings

Learn the proper techniques for connecting and disassembling Galvanized Pipe Fittings with our comprehensive guide

12/14/2020

Prior to around 1960, galvanized steel pipe was a popular alternative to lead pipe for home water supply lines. This type of steel pipe is coated in zinc to protect it from corrosion and rust. The problem is, over the years some galvanized steel pipes may start to rust from the inside out, which can cause reduced water pressure and the potential for flood-causing leaks or ruptures.

Today, most DIY work involving galvanized pipe is related to repairs of existing older pipes versus installation of totally new plumbing systems, which have shifted mostly to plastic piping or even copper.

Important note: If you plan to make repairs to existing galvanized steel pipes that incorporate plastic or copper piping, you should purchase specialized galvanized pipe fittings to prevent premature corrosion that can happen by joining different types of metal.

However, if you plan to repair galvanized pipes using similarly galvanized iron fittings, simply follow the steps below.

Connecting Non-Threaded Galvanized Pipe

Step 1: Measure

If you are connecting galvanized pipes that are not already threaded, you’ll need to use a galvanized iron coupling that creates a properly sealed joint. Failure to use the correct coupling can cause damaging leaks, mostly due to the rough edges most galvanized pipes have as a result of the zinc coating.

First, measure the diameter of each pipe with a tape measure. If they are the same diameter, you can go with a standard coupling. If they are different, you’ll need to purchase a stepped coupling that steps up in size to match the connecting pipe.

To properly measure the diameter of the pipe, remember that the diameter of the inside of the pipe is different than the outside. For example, even if the outside diameter of the galvanized steel pipe you’re working with measures ¾", you’ll need a coupling that matches the interior diameter where the pipe and the coupling meet. A pipe that has a ¾" outside diameter should have an interior diameter that measures ½", and that’s the coupling size you should purchase.

Step 2: Check the coating

As mentioned above, is the surface of the pipe rough? If it is, you’ll need to procure a specialized coupling that is designed for rough and uneven surfaces. (Ask the plumbing expert at your local hardware store.) A smooth surface means a standard coupling should work just fine.

Step 3: Prepare the pipe

Before joining, use a level to make sure the end of the unthreaded pipe is perfectly square. If it isn’t, you’ll need to use a saw to cut it to square and sand down the edges. Then, wipe the pipe with a water-based degreaser. Place the coupling up to the center of the pipe joint and mark a line on each end of the coupling using a grease pencil.

Step 4: Connect the pipes

Place one end of the non-threaded pipe into the coupling and align the end with the pencil line on the pipe. Do the same with the second pipe and be sure to center the coupling between the two lines. Then, tighten the fastening bolts so the coupling holds the pipes securely. If needed, a torque wrench can be used to evenly tighten the bolts.

Connecting Threaded Galvanized Pipe

If you are connecting threaded galvanized pipe, you’ll need to coat all of the threads with what’s known as pipe dope—a common thread lubricant and sealing compound—or wrap the threads with PTFE (short for polytetrafluoroethylene) plumber’s tape. This helps secure a water-tight connection.

After getting the connection hand-tight, use one pipe wrench to hold the pipe in place and the other to tighten the fitting.

Loosening Galvanized Pipe Fittings

If you want to loosen galvanized pipe fittings that have become corroded, you’ll need to use a loosening agent to help the cause. Start by turning off the water that flows to the section of pipe that you’re working on, and spray some penetrating oil where the threaded pipe connects with the fitting that is being removed.

Place one pipe wrench onto the lock nut and the other on the retaining nut. Loosen the connection by turning the nut counter-clockwise.

Then, hold the fitting securely with one of the pipe wrenches and use the other pipe wrench to turn the loose piece of pipe that is connected to the fitting. Turn the wrench on the loose pipe counter-clockwise and remove the galvanized fitting.

Next, move the wrench that was on the loose pipe to the pipe on the other side of the fitting you are removing. Again, turn the wrench counter-clockwise and the fitting should come free. If you need additional leverage, place a piece of pipe over the handle of the wrench and press downward.

Once you know how to join and loosen galvanized pipe fittings, you’ll be equipped to make the many necessary repairs in older homes. This can save you significant dollars during a renovation project by reducing the chances of having to fully replace all of the galvanized steel pipes with new plastic piping.

https://www.archtoolbox.com/standard-pipe-dimensions/

Standard Pipe Dimensions

Materials & Systems > Plumbing

Pipe dimensions vary based on the schedule and material. There is quite a bit that goes into the dimensions, but you can use the table of contents if you want to skip all of that and jump directly to the pipe size charts.

ARTICLE CONTENTS

Nominal Pipe Size

Nominal Pipe Size (abbreviated NPS) is a North American standard for identifying pipe sizes. Technically, the NPS is non-dimensional and only roughly refers to the diameter of the pipe. However, from NPS 14 and above, the NPS value matches the outside diameter of the pipe. Nominal Pipe Sizes apply to all materials of pipe. When specific pipes are specified, the NPS, Schedule, and material are required.

Outside of North America, pipes are identified by Diametre Nominel (DN), which is a dimensionless value that roughly equates to the outside diameter of the pipe in mm. The DN dimensions must conform to ISO Standard 6708.

Understanding Pipe Schedule Terminology

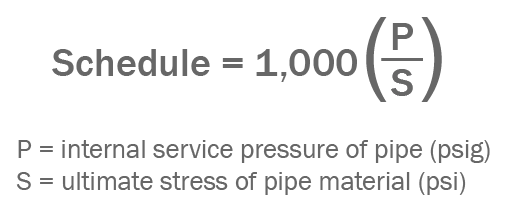

While the Nominal Pipe Size identifies the outside diameter of the pipe, more information is needed to identify specific pipes. A pipe's schedule is the thickness of the pipe wall, which directly affects the interior dimension and weight of the pipe. Wall thickness is important because it determines the amount of internal pressure that the pipe can withstand. The schedule number is roughly calculated as: Schedule = 1000 x (P/S) where P is the internal service pressure of the pipe (psig) and S is the ultimate tensile strength of the pipe material (psi).

Pipe Schedule Formula

Pipe Schedule Formula

In addition to the schedule numbers, you will often see Standard (STD), Extra Strong (XS), and Double Extra Strong (XXS). These were original terms used prior to the schedule system that was implemented in 1927. It was originally intended for these to be phased out, but they occasionally appear. Stainless Steel pipe schedules append an "S" to the end of the schedule number, for instance Schedule 40S.

The two most common schedule sizes seen in buildings are Schedule 40 and Schedule 80. However, some process piping, utility facilities, and civil piping may require higher schedule numbers depending on the pressures used.

Pipes vs. Tubes

Pipes are used to transport gases or fluids. As stated above, they are measured with nominal outside diameters using NPS and Schedule to define the pipe size.

On the other hand, tubes are structural members and are measured with an exact outside diameter. Tubing is measured by the exact outside diameter and the wall thickness (WT). The manufacturing tolerances are much tighter than in pipes.

Steel Pipe Sizes – Schedule 40

| NPS | OUTSIDE DIAMETER (IN) | INSIDE DIAMETER (IN) | WALL THICKNESS (IN) | WEIGHT (LB/FT) |

|---|---|---|---|---|

| 1/8 | 0.405" | 0.269" | 0.068" | 0.24 lb/ft |

| 1/4 | 0.540" | 0.364" | 0.088" | 0.42 lb/ft |

| 3/8 | 0.675" | 0.493" | 0.091" | 0.57 lb/ft |

| 1/2 | 0.840" | 0.622" | 0.109" | 0.85 lb/ft |

| 3/4 | 1.050" | 0.824" | 0.113" | 1.13 lb/ft |

| 1 | 1.315" | 1.049" | 0.133" | 1.68 lb/ft |

| 1-1/4 | 1.660" | 1.380" | 0.140" | 2.27 lb/ft |

| 1-1/2 | 1.900" | 1.610" | 0.145" | 2.72 lb/ft |

| 2 | 2.375" | 2.067" | 0.154" | 3.65 lb/ft |

| 2-1/2 | 2.875" | 2.469" | 0.203" | 5.79 lb/ft |

| 3 | 3.500" | 3.068" | 0.216" | 7.58 lb/ft |

| 3-1/2 | 4.000" | 3.548" | 0.226" | 9.11 lb/ft |

| 4 | 4.500" | 4.026" | 0.237" | 10.79 lb/ft |

| 5 | 5.563" | 5.047" | 0.258" | 14.62 lb/ft |

| 6 | 6.625" | 6.065" | 0.280" | 18.97 lb/ft |

| 8 | 8.625" | 7.981" | 0.322" | 28.55 lb/ft |

| 10 | 10.750" | 10.020" | 0.365" | 40.48 lb/ft |

| 12 | 12.75" | 11.938" | 0.406" | 53.52 lb/ft |

| 14 | 14.000" | 13.124" | 0.438" | 63.50 lb/ft |

| 16 | 16.000" | 15.000" | 0.500" | 82.77 lb/ft |

| 18 | 18.000" | 16.876" | 0.562" | 104.70 lb/ft |

| 20 | 20.000" | 18.812" | 0.594" | 123.10 lb/ft |

| 24 | 24.000" | 22.624" | 0.688" | 171.30 lb/ft |

Steel Pipe Sizes – Schedule 80

| NPS | OUTSIDE DIAMETER (IN) | INSIDE DIAMETER (IN) | WALL THICKNESS (IN) | WEIGHT (LB/FT) |

|---|---|---|---|---|

| 1/8 | 0.405" | 0.215" | 0.095" | 0.32 lb/ft |

| 1/4 | 0.540" | 0.302" | 0.119" | 0.54 lb/ft |

| 3/8 | 0.675" | 0.423" | 0.126" | 0.74 lb/ft |

| 1/2 | 0.840" | 0.546" | 0.147" | 1.09 lb/ft |

| 3/4 | 1.050" | 0.742" | 0.154" | 1.47 lb/ft |

| 1 | 1.315" | 0.957" | 0.179" | 2.17 lb/ft |

| 1-1/4 | 1.660" | 1.278" | 0.191" | 3.00 lb/ft |

| 1-1/2 | 1.900" | 1.500" | 0.200" | 3.63 lb/ft |

| 2 | 2.375" | 1.939" | 0.218" | 5.02 lb/ft |

| 2-1/2 | 2.875" | 2.323" | 0.276" | 7.66 lb/ft |

| 3 | 3.500" | 2.900" | 0.300" | 10.25 lb/ft |

| 3-1/2 | 4.000" | 3.364" | 0.318" | 12.50 lb/ft |

| 4 | 4.500" | 3.826" | 0.337" | 14.98 lb/ft |

| 5 | 5.563" | 4.813" | 0.375" | 20.78 lb/ft |

| 6 | 6.625" | 5.761" | 0.432" | 28.57 lb/ft |

| 8 | 8.625" | 7.625" | 0.500" | 43.39 lb/ft |

| 10 | 10.750" | 9.562" | 0.594" | 64.42 lb/ft |

| 12 | 12.75" | 11.374" | 0.688" | 88.63 lb/ft |

| 14 | 14.000" | 12.500" | 0.750" | 106.10 lb/ft |

| 16 | 16.000" | 14.312" | 0.844" | 136.58 lb/ft |

| 18 | 18.000" | 16.124" | 0.938" | 170.87 lb/ft |

| 20 | 20.000" | 17.938" | 1.031" | 208.92 lb/ft |

| 24 | 24.000" | 21.562" | 1.219" | 296.58 lb/ft |

Stainless Steel Pipe Sizes – Schedule 40S

| NPS | OUTSIDE DIAMETER (IN) | INSIDE DIAMETER (IN) | WALL THICKNESS (IN) | WEIGHT (LB/FT) |

|---|---|---|---|---|

| 1/8 | 0.405" | 0.269" | 0.068" | 0.25 lb/ft |

| 1/4 | 0.540" | 0.364" | 0.088" | 0.40 lb/ft |

| 3/8 | 0.675" | 0.493" | 0.091" | 0.58 lb/ft |

| 1/2 | 0.840" | 0.622" | 0.109" | 0.87 lb/ft |

| 3/4 | 1.050" | 0.824" | 0.113" | 1.20 lb/ft |

| 1 | 1.315" | 1.049" | 0.133" | 1.68 lb/ft |

| 1-1/4 | 1.660" | 1.380" | 0.140" | 2.27 lb/ft |

| 1-1/2 | 1.900" | 1.610" | 0.145" | 2.72 lb/ft |

| 2 | 2.375" | 2.067" | 0.154" | 3.65 lb/ft |

| 2-1/2 | 2.875" | 2.469" | 0.203" | 5.79 lb/ft |

| 3 | 3.500" | 3.068" | 0.216" | 7.58 lb/ft |

| 3-1/2 | 4.000" | 3.548" | 0.226" | 9.11 lb/ft |

| 4 | 4.500" | 4.026" | 0.237" | 10.79 lb/ft |

| 5 | 5.563" | 5.047" | 0.258" | 14.62 lb/ft |

| 6 | 6.625" | 6.065" | 0.280" | 18.97 lb/ft |

| 8 | 8.625" | 7.981" | 0.322" | 28.55 lb/ft |

| 10 | 10.750" | 10.020" | 0.365" | 40.48 lb/ft |

| 12 | 12.75" | 12.000" | 0.375" | 49.56 lb/ft |

| 14 | 14.000" | 13.250" | 0.375" | 54.57 lb/ft |

| 16 | 16.000" | 15.250" | 0.375" | 62.58 lb/ft |

| 18 | 18.000" | 17.250" | 0.375" | 70.59 lb/ft |

| 20 | 20.000" | 19.250" | 0.375" | 78.60 lb/ft |

| 24 | 24.000" | 23.250" | 0.375" | 94.62 lb/ft |

Stainless Steel Pipe Sizes – Schedule 80S

| NPS | OUTSIDE DIAMETER (IN) | INSIDE DIAMETER (IN) | WALL THICKNESS (IN) | WEIGHT (LB/FT) |

|---|---|---|---|---|

| 1/8 | 0.405" | 0.215" | 0.095" | 0.32 lb/ft |

| 1/4 | 0.540" | 0.302" | 0.119" | 0.54 lb/ft |

| 3/8 | 0.675" | 0.423" | 0.126" | 0.74 lb/ft |

| 1/2 | 0.840" | 0.546" | 0.147" | 1.09 lb/ft |

| 3/4 | 1.050" | 0.742" | 0.154" | 1.47 lb/ft |

| 1 | 1.315" | 0.957" | 0.179" | 2.17 lb/ft |

| 1-1/4 | 1.660" | 1.278" | 0.191" | 3.00 lb/ft |

| 1-1/2 | 1.900" | 1.500" | 0.200" | 3.63 lb/ft |

| 2 | 2.375" | 1.939" | 0.218" | 5.02 lb/ft |

| 2-1/2 | 2.875" | 2.323" | 0.276" | 7.66 lb/ft |

| 3 | 3.500" | 2.900" | 0.300" | 10.25 lb/ft |

| 3-1/2 | 4.000" | 3.364" | 0.318" | 12.50 lb/ft |

| 4 | 4.500" | 3.826" | 0.337" | 14.98 lb/ft |

| 5 | 5.563" | 4.813" | 0.375" | 20.78 lb/ft |

| 6 | 6.625" | 5.761" | 0.432" | 28.57 lb/ft |

| 8 | 8.625" | 7.625" | 0.500" | 43.39 lb/ft |

| 10 | 10.750" | 9.750" | 0.500" | 54.74 lb/ft |

| 12 | 12.75" | 11.750" | 0.500" | 65.42 lb/ft |

| 14 | 14.000" | 13.000" | 0.500" | 72.09 lb/ft |

| 16 | 16.000" | 15.000" | 0.500" | 82.77 lb/ft |

| 18 | 18.000" | 17.000" | 0.500" | 93.45 lb/ft |

| 20 | 20.000" | 19.000" | 0.500" | 104.10 lb/ft |

| 24 | 24.000" | 23.000" | 0.500" | 125.50 lb/ft |

Polyvinyl Chloride (PVC) Pipe Sizes – Schedule 40

Chlorinated Polyvinyl Chloride (CPVC) has the same dimensions as PVC, but weighs slightly more than PVC

| NPS | OUTSIDE DIAMETER (IN) | INSIDE DIAMETER (IN) | WALL THICKNESS (IN) | WEIGHT (LB/FT) |

|---|---|---|---|---|

| 1/8 | 0.405" | 0.269" | 0.068" | 0.05 lb/ft |

| 1/4 | 0.540" | 0.364" | 0.088" | 0.09 lb/ft |

| 3/8 | 0.675" | 0.493" | 0.091" | 0.12 lb/ft |

| 1/2 | 0.840" | 0.622" | 0.109" | 0.17 lb/ft |

| 3/4 | 1.050" | 0.824" | 0.113" | 0.23 lb/ft |

| 1 | 1.315" | 1.049" | 0.133" | 0.33 lb/ft |

| 1-1/4 | 1.660" | 1.380" | 0.140" | 0.45 lb/ft |

| 1-1/2 | 1.900" | 1.610" | 0.145" | 0.54 lb/ft |

| 2 | 2.375" | 2.067" | 0.154" | 0.72 lb/ft |

| 2-1/2 | 2.875" | 2.469" | 0.203" | 1.14 lb/ft |

| 3 | 3.500" | 3.068" | 0.216" | 1.49 lb/ft |

| 3-1/2 | 4.000" | 3.548" | 0.226" | 1.79 lb/ft |

| 4 | 4.500" | 4.026" | 0.237" | 2.19 lb/ft |

| 5 | 5.563" | 5.047" | 0.258" | 2.87 lb/ft |

| 6 | 6.625" | 6.065" | 0.280" | 3.73 lb/ft |

| 8 | 8.625" | 7.981" | 0.322" | 5.62 lb/ft |

| 10 | 10.750" | 10.020" | 0.365" | 7.97 lb/ft |

| 12 | 12.75" | 11.938" | 0.406" | 10.53 lb/ft |

| 14 | 14.000" | 13.126" | 0.437" | 12.46 lb/ft |

| 16 | 16.000" | 15.000" | 0.500" | 16.29 lb/ft |

| 18 | 18.000" | 16.876" | 0.562" | 20.59 lb/ft |

| 20 | 20.000" | 18.814" | 0.593" | 24.18 lb/ft |

| 24 | 24.000" | 22.626" | 0.687" | 33.65 lb/ft |

Polyvinyl Chloride (PVC) Pipe Sizes – Schedule 80

Chlorinated Polyvinyl Chloride (CPVC) has the same dimensions as PVC, but weighs slightly more than PVC

| NPS | OUTSIDE DIAMETER (IN) | INSIDE DIAMETER (IN) | WALL THICKNESS (IN) | WEIGHT (LB/FT) |

|---|---|---|---|---|

| 1/8 | 0.405" | 0.215 | 0.095 | 0.06 lb/ft |

| 1/4 | 0.540" | 0.302" | 0.119" | 0.11 lb/ft |

| 3/8 | 0.675" | 0.423" | 0.126" | 0.15 lb/ft |

| 1/2 | 0.840" | 0.546" | 0.147" | 0.21 lb/ft |

| 3/4 | 1.050" | 0.742" | 0.154" | 0.29 lb/ft |

| 1 | 1.315" | 0.957" | 0.179" | 0.42 lb/ft |

| 1-1/4 | 1.660" | 1.278" | 0.191" | 0.59 lb/ft |

| 1-1/2 | 1.900" | 1.5" | 0.200" | 0.71 lb/ft |

| 2 | 2.375" | 1.939" | 0.218" | 0.98 lb/ft |

| 2-1/2 | 2.875" | 2.323" | 0.276" | 1.50 lb/ft |

| 3 | 3.500" | 2.900" | 0.300" | 2.10 lb/ft |

| 3-1/2 | 4.000" | 3.364" | 0.318" | 2.45 lb/ft |

| 4 | 4.500" | 3.826" | 0.337" | 2.94 lb/ft |

| 5 | 5.563" | 4.813" | 0.375" | 4.08 lb/ft |

| 6 | 6.625" | 5.761" | 0.432" | 5.61 lb/ft |

| 8 | 8.625" | 7.625" | 0.500" | 8.52 lb/ft |

| 10 | 10.750" | 9.562" | 0.594" | 12.64 lb/ft |

| 12 | 12.75" | 11.374" | 0.688" | 17.38 lb/ft |

| 14 | 14.000" | 12.500" | 0.750" | 20.85 lb/ft |

| 16 | 16.000" | 14.312" | 0.844" | 26.81 lb/ft |

| 18 | 18.000" | 16.124" | 0.938" | 33.54 lb/ft |

| 20 | 20.000" | 17.938" | 1.031" | 41.05 lb/ft |

| 24 | 24.000" | 21.562" | 1.219" | 58.23 lb/ft |

Article Updated: October 3, 2021

https://www.zoro.com/resourcehub/how-to-measure-pipe-and-fitting-sizes/

How to Measure Pipe and Fitting Sizes

Concise guide that covers the key aspects of pipe and fitting measurements. It is an essential tool for anyone working with pipes and fittings.

Determining what size pipes you need for your project can be confusing. Many people assume pipe size is the outer diameter of the pipe—but “pipe size” actually refers to what is called “nominal diameter.”

Fittings can be just as confusing. Their inside diameters must be large enough to fit over the pipe's outside diameter. A half-inch plastic elbow, for example, has an outside diameter of about 1-1/4 inches.

Use this guide to help you find the pipe and fitting sizes you need for your next project.

How To Measure Pipes and Tubes

Convert Actual Diameter to Nominal Diameter

The easiest way to find what nominal pipe size you need is to use follow these steps and use the conversion chart below.

| For Female Threads1. Measure the Inside Diameter (ID) of your pipe or pipe fitting (use a ruler or tape measure).2. Use the chart on this page to find the nominal diameter (pipe size). |  |

|---|---|

Nominal Diameter Conversion Chart

(All Measurements in Inches)

| Outside or Inside Diameter | Decimal Equivalent | Nominal Diameter | Typical Threads Per Inch |

|---|---|---|---|

| 5/16 | 0.313 | 1/16 | 27 |

| 13/32 | 0.405 | 1/8 | 27 |

| 35/64 | 0.540 | 1/4 | 18 |

| 43/64 | 0.675 | 3/8 | 18 |

| 27/32 | 0.840 | 1/2 | 14 |

| 1-3/64 | 1.050 | 3/4 | 14 |

| 1-5/16 | 1.315 | 1 | 11-1/2 |

| 1-21/32 | 1.660 | 1-1/4 | 11-1/2 |

| 1-29/32 | 1.900 | 1-1/2 | 11-1/2 |

| 2-3/8 | 2.375 | 2 | 11-1/2 |

| 2-7/8 | 2.875 | 2-1/2 | 8 |

| 3-1/2 | 3.500 | 3 | 8 |

| 4 | 4.000 | 3-1/2 | 8 |

| 4-1/2 | 4.500 | 4 | 8 |

Pipes vs. Tubing

Pipes vs. Tubing

Pipe and tubing are not measured the same way. Tubing is measured and named based on the actual outside diameter of the tube.

PEX, or Cross-Linked Polyethylene Tubing, is another technology fast becoming popular, and it is measured and named by inside diameter.

Example:

| Pipe vs. Tubing | Outside Diameter |

|---|---|

| 1/2” size pipe | 27/32” |

| 1/2” size tubing | 1/2” |

Select Thread Type

One of the most common thread types is National Pipe Thread (NPT). These come in male (NPT, MPT, or MNPT) and female (FPT or FNPT). These are usually tapered threads used in joining and sealing pipes.

Another common thread is National Standard Free-Fitting Straight Mechanical Pipe Thread (NPSM). These straight thread pipes are typically used for mechanical joints.

BSP thread form stands for British Standard Pipe. It is based on trade size rather than actual diameter.

Shop Pipes and Fittings

Select the plumbing application you need for your next project.

| Pipes & Pipe NipplesShop All Pipes | Black PipesStainless Steel PipesGalvanized PipesBrass PipesPVC & CPVC Pipes |

|---|---|

FittingsShop All Fittings

Product Compliance and Suitability

The product statements contained in this guide are intended for general informational purposes only. Such product statements do not constitute a product recommendation or representation as to the appropriateness, accuracy, completeness, correctness or currentness of the information provided. Information provided in this guide does not replace the use by you of any manufacturer instructions, technical product manual, or other professional resource or adviser available to you. Always read, understand and follow all manufacturer instructions.

PVC Pipe Sizes: A Guide To Sizes and Dimensions

Discover the essential information about PVC pipe sizes and dimensions in this guide. Learn more about pipes and find the right fit for your project.

3/19/2021 – Zoro Staff

Depending on the project at hand, you may need to buy new PVC pipes. PVC pipes vary in size and are broken down into three main categories: schedule 40, schedule 80, and schedule 120. To avoid misuse, plumbing malfunctions, or pushing back a piping project, it’s helpful to do your research and find the right product fit. It could save you and your team time and money from reordering materials or fixing future pipe issues.

PVC pipes are measured on a nominal system. This means all measurements are based on the types of structures versus specific measurements. For instance, 0.84 inches measured from one pipe's end to another is classified as a one-inch pipe. There are also different uses for each type of pipe schedule. Keep reading to understand each PVC pipe's size and uses for your next job.

How to Measure Your Current PVC Pipe Size

| Your Measurement | Average Outer Diameter (OD) |

|---|---|

| Diameter | PVC Pipe Size Translation |

| 0.84” | ½” |

| 1.05” | ¾” |

| 1.315” | 1” |

| 1.66” | 1 ¼” |

| 1.9” | 1 ½” |

| 2.375” | 2” |

| 3.5” | 3” |

| 4” | 3 ½” |

| 4.5” | 4” |

| 5.563” | 5” |

| 6.625” | 6” |

| 8.625” | 8” |

| 10.75” | 10” |

| *Works for Schedule 40 and Schedule 80 PVC pipes. |

Pipe measurements are calculated on a nominal scale. This means their measurements reference structures at hand over true scale measurements. To help translate the correct size of pipes you need, we included a helpful guide above.

Here’s a step-by-step guide to using the chart:

- Place your pipe on a hard surface and face one end towards you.

- Grab a tape measure or ruler to measure your pipe’s right outer edge to its left outer edge. Keep your ruler as level as possible while measuring.

- Now, pair “Your Measurement” with the “Average OD” referencing the chart above.

- Pick out your pipes based on the Average OD your measurement paired with.

Keep in mind, these measurements refer to the outer edge of the pipe, not the inner. Depending on the schedule of pipe you need, your inner measurements may fluctuate.

Schedule 40 PVC Pipe Dimensions

| Nominal Pipe Size (Inches) | Outside Diameter (OD) | Min. Wall Thickness | Inside Diameter (ID) | Linear Weight Density (Wt. / Ft.) |

|---|---|---|---|---|

| 1/8 | 0.405 | 0.068 | 0.249 | 0.051 |

| 1/4 | 0.540 | 0.086 | 0.344 | 0.086 |

| 3/8 | 0.675 | 0.091 | 0.473 | 0.115 |

| 1/2 | 0.840 | 0.109 | 0.602 | 0.170 |

| 3/4 | 1.050 | 0.113 | 0.804 | 0.226 |

| 1 | 1.315 | 0.133 | 1.029 | 0.333 |

| 1 1/4 | 1.660 | 0.140 | 1.360 | 0.450 |

| 1 1/2 | 1.900 | 0.145 | 1.590 | 0.537 |

| 2 | 2.375 | 0.154 | 2.047 | 0.720 |

| 2 1/2 | 2.875 | 0.203 | 2.445 | 1.136 |

| 3 | 3.500 | 0.216 | 3.042 | 1.488 |

| 3 1/2 | 4.000 | 0.226 | 3.521 | 1.789 |

| 4 | 4.500 | 0.237 | 3.998 | 2.118 |

| 5 | 5.563 | 0.258 | 5.016 | 2.874 |

| 6 | 6.625 | 0.280 | 6.031 | 3.733 |

| 8 | 8.625 | 0.322 | 7.942 | 5.619 |

| 10 | 10.750 | 0.365 | 9.976 | 7.966 |

| 12 | 12.750 | 0.406 | 11.889 | 10.534 |

| 14 | 14.000 | 0.437 | 13.073 | 12.462 |

| 16 | 16.000 | 0.500 | 14.940 | 16.286 |

| 18 | 18.000 | 0.562 | 16.809 | 20.587 |

| 20 | 20.000 | 0.593 | 18.743 | 24.183 |

| 24 | 24.000 | 0.687 | 22.544 | 33.652 |

Schedule 40 pipes are typically white or silver but can be found in other colors. These pipes are thinner than schedule 80s and 120s. This allows fluids to pass through faster than other pipe schedules. This style upholds great pressure, even for cold water systems. In hot temperatures, all three schedules are able to withstand up to 140 degrees.

Schedule 40 pipes are commonly used for drainage around buildings and for gas and water lines. The pressure rating for this pipe schedule is 120 to 810 pounds per second inch (PSI). As a result, schedule 40 pipes are commonly used for potable water systems, golf course construction, or pools and spas.

Schedule 80 PVC Pipe Dimensions

| Nominal Pipe Size (Inches) | Outside Diameter (OD) | Min. Wall Thickness | Inside Diameter (ID) | Linear Weight Density (Wt. / Ft.) |

|---|---|---|---|---|

| 1/8 | 0.405 | 0.095 | 0.195 | 0.068 |

| 1/4 | 0.540 | 0.119 | 0.288 | 0.110 |

| 3/8 | 0.675 | 0.126 | 0.407 | 0.153 |

| 1/2 | 0.840 | 0.147 | 0.546 | 0.225 |

| 3/4 | 1.050 | 0.154 | 0.742 | 0.305 |

| 1 | 1.315 | 0.179 | 0.957 | 0.450 |

| 1 1/4 | 1.660 | 1.191 | 1.278 | 0.621 |

| 1 1/2 | 1.900 | 0.200 | 1.500 | 0.754 |

| 2 | 2.375 | 0.218 | 1.939 | 1.043 |

| 2 1/2 | 2.875 | 0.276 | 2.290 | 1.594 |

| 3 | 3.500 | 0.300 | 2.864 | 2.132 |

| 4 | 4.500 | 0.337 | 3.786 | 3.116 |

| 6 | 6.625 | 0.432 | 5.709 | 5.951 |

| 8 | 8.625 | 0.500 | 7.565 | 9.040 |

| 10 | 10.750 | 0.593 | 9.493 | 13.413 |

| 12 | 12.750 | 0.687 | 11.294 | 18.440 |

| 14 | 14.000 | 0.750 | 12.410 | 22.119 |

| 16 | 16.000 | 0.843 | 14.213 | 28.424 |

| 18 | 18.000 | 0.937 | 16.014 | 36.487 |

| 20 | 20.000 | 1.031 | 17.814 | 44.648 |

| 24 | 24.000 | 1.218 | 21.418 | 36.341 |

Schedule 80 pipes are thicker than schedule 40 pipes, but still not the thickest. These pipes are usually dark gray in color but may vary. Schedule 80 PVC pipes are built thicker and stronger than schedule 40s, and can handle higher pressures with a rating of 210 to 1230 PSI. They’re often used for chemical processing, industrial plating, deionized water lines, and wastewater treatment management.

Keep in mind, the thicker the pipe does not equal pipe security. Depending on the solutions you’d be transporting and the flow rate you’d like, mishaps can happen if you don’t choose the correct size and fit. For instance, if you use a heavy pipe for general solution purposes, your flow could be slower than needed.

Schedule 120 PVC Pipe Dimensions

| Nominal Pipe Size (Inches) | Outside Diameter (OD) | Min. Wall Thickness | Inside Diameter (ID) | Linear Weight Density (Wt. / Ft.) |

|---|---|---|---|---|

| 1/2 | 0.840 | 0.170 | 0.480 | 0.236 |

| 3/4 | 1.050 | 0.170 | 0.690 | 0.311 |

| 1 | 1.320 | 0.200 | 0.891 | 0.464 |

| 1 1/4 | 1.660 | 0.215 | 1.204 | 0.649 |

| 1 1/2 | 1.900 | 0.225 | 1.423 | 0.787 |

| 2 | 2.380 | 0.250 | 1.84 | 1.111 |

| 2 1/2 | 2.880 | 0.300 | 2.239 | 1.615 |

| 3 | 3.500 | 0.350 | 2.758 | 2.306 |

| 4 | 4.500 | 0.430 | 3.574 | 19.000 |

| 6 | 6.625 | 0.532 | 5.434 | 36.390 |

| 8 | 8.625 | 0.719 | 7.189 | 60.440 |

| 10 | 10.750 | 0.844 | – | 98.290 |

| 12 | 12.750 | 1.000 | – | 125.490 |

| 14 | 14.000 | 1.094 | – | 150.790 |

| 16 | 16.000 | 1.219 | – | 192.430 |

| 18 | 18.000 | 1.375 | – | 244.140 |

| 20 | 20.000 | 1.500 | – | 296.370 |

| 22 | 22.000 | 1.625 | – | 353.610 |

| 24 | 24.000 | 1.812 | – | 429.390 |

Schedule 120 pipes are one of the thickest pipes on the market. With their density, they’re routinely used for non-corrosive or general corrosive projects with less reactive ingredients. Automotive and construction establishments frequently use these materials for maximum durability. Schedule 120’s pipe thickness helps slow down mild to high-pressure systems with a rating of 380 to 1,010 PSI.

Depending on the construction site you’re working on, contact your state for building code regulations. To avoid miscommunication, ensure you find out pipe schedules needed to properly meet local requirements.

Once you have your pipe sizes figured out, you’ll be able to move onto the next step: ordering pipe values. To help control your pipe flow, figure out which size valves you may need. When you’re ready to install your pipes and valves, be sure to reference our guide. As your team needs more materials or installation information, be sure to reference Zoro’s site for expert tips, tricks, and product needs.

Sources: Hunker

< hr>

How to Join and Loosen Galvanized Pipe Fittings

Learn the proper techniques for connecting and disassembling Galvanized Pipe Fittings with our comprehensive guide

12/14/2020

Prior to around 1960, galvanized steel pipe was a popular alternative to lead pipe for home water supply lines. This type of steel pipe is coated in zinc to protect it from corrosion and rust. The problem is, over the years some galvanized steel pipes may start to rust from the inside out, which can cause reduced water pressure and the potential for flood-causing leaks or ruptures.

Today, most DIY work involving galvanized pipe is related to repairs of existing older pipes versus installation of totally new plumbing systems, which have shifted mostly to plastic piping or even copper.

Important note: If you plan to make repairs to existing galvanized steel pipes that incorporate plastic or copper piping, you should purchase specialized galvanized pipe fittings to prevent premature corrosion that can happen by joining different types of metal.

However, if you plan to repair galvanized pipes using similarly galvanized iron fittings, simply follow the steps below.

Connecting Non-Threaded Galvanized Pipe

Step 1: Measure

If you are connecting galvanized pipes that are not already threaded, you’ll need to use a galvanized iron coupling that creates a properly sealed joint. Failure to use the correct coupling can cause damaging leaks, mostly due to the rough edges most galvanized pipes have as a result of the zinc coating.

First, measure the diameter of each pipe with a tape measure. If they are the same diameter, you can go with a standard coupling. If they are different, you’ll need to purchase a stepped coupling that steps up in size to match the connecting pipe.

To properly measure the diameter of the pipe, remember that the diameter of the inside of the pipe is different than the outside. For example, even if the outside diameter of the galvanized steel pipe you’re working with measures ¾", you’ll need a coupling that matches the interior diameter where the pipe and the coupling meet. A pipe that has a ¾" outside diameter should have an interior diameter that measures ½", and that’s the coupling size you should purchase.

Step 2: Check the coating

As mentioned above, is the surface of the pipe rough? If it is, you’ll need to procure a specialized coupling that is designed for rough and uneven surfaces. (Ask the plumbing expert at your local hardware store.) A smooth surface means a standard coupling should work just fine.

Step 3: Prepare the pipe

Before joining, use a level to make sure the end of the unthreaded pipe is perfectly square. If it isn’t, you’ll need to use a saw to cut it to square and sand down the edges. Then, wipe the pipe with a water-based degreaser. Place the coupling up to the center of the pipe joint and mark a line on each end of the coupling using a grease pencil.

Step 4: Connect the pipes

Place one end of the non-threaded pipe into the coupling and align the end with the pencil line on the pipe. Do the same with the second pipe and be sure to center the coupling between the two lines. Then, tighten the fastening bolts so the coupling holds the pipes securely. If needed, a torque wrench can be used to evenly tighten the bolts.

Connecting Threaded Galvanized Pipe

If you are connecting threaded galvanized pipe, you’ll need to coat all of the threads with what’s known as pipe dope—a common thread lubricant and sealing compound—or wrap the threads with PTFE (short for polytetrafluoroethylene) plumber’s tape. This helps secure a water-tight connection.

After getting the connection hand-tight, use one pipe wrench to hold the pipe in place and the other to tighten the fitting.

Loosening Galvanized Pipe Fittings

If you want to loosen galvanized pipe fittings that have become corroded, you’ll need to use a loosening agent to help the cause. Start by turning off the water that flows to the section of pipe that you’re working on, and spray some penetrating oil where the threaded pipe connects with the fitting that is being removed.

Place one pipe wrench onto the lock nut and the other on the retaining nut. Loosen the connection by turning the nut counter-clockwise.

Then, hold the fitting securely with one of the pipe wrenches and use the other pipe wrench to turn the loose piece of pipe that is connected to the fitting. Turn the wrench on the loose pipe counter-clockwise and remove the galvanized fitting.

Next, move the wrench that was on the loose pipe to the pipe on the other side of the fitting you are removing. Again, turn the wrench counter-clockwise and the fitting should come free. If you need additional leverage, place a piece of pipe over the handle of the wrench and press downward.

Once you know how to join and loosen galvanized pipe fittings, you’ll be equipped to make the many necessary repairs in older homes. This can save you significant dollars during a renovation project by reducing the chances of having to fully replace all of the galvanized steel pipes with new plastic piping.